Then contact us to receive a free online live presentation carried out by our experts!

Highest safety standards, complete utilization of your lining’s durability, leading to no break-outs: These are just some of the requirements that you as a steelwork manager face on a daily basis. Ensuring that logistical requirements are met and ensuring a balance between inadequacies of operating personnel and technology are other necessary aspects in achieving maximum refractory performance.

Gregor Lammer

APO Product Owner

APO enhances the prediction of a linings’ lifetime. With the support of your digital twin, you can interpret the parameters influencing the wear more efficiently. This is achieved by analyzing the data in an external data center using artificial intelligence methods.

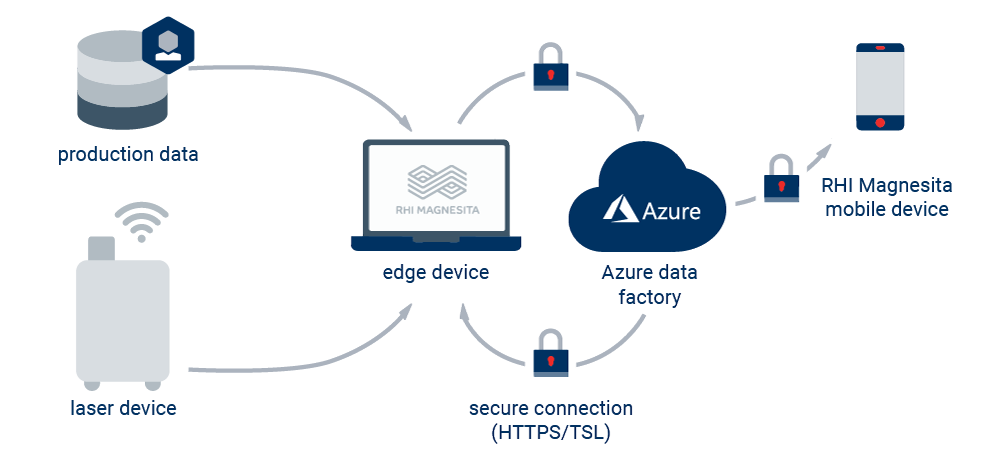

Your production data, including the information gathered by the laser device, is transferred directly to the RHI Magnesita external center. In this process, you can access the linings’ lifetime report via the RHI Magnesita edge mobile device provided by RHI Magnesita. A secure connection is guaranteed.

In addition, after each measurement, the lining condition is displayed to you everywhere, including on mobile devices.

Please fill out the form. Once we have received your inquiry one of our experts will contact you to arrange an appointment which suits you the best.