Safety comes first, especially in the steel, metal and non-ferrous industries. The risk of ladle breakouts will always be present when handling liquid metal and you have to deal with equipment damage, personnel injuries and loss of production as a consequence.

Therefore, ladle refractories undergo a timely exchange, even though they could last a few more heats. We provide a solution which lets you control your ladles status and further increase the safety of your operations: VISIR – LadleSafe.

VISIR FurnaceSafe:

LF breakout prevention

VISIR LadleDeslag:

Ladle skimming monitoring

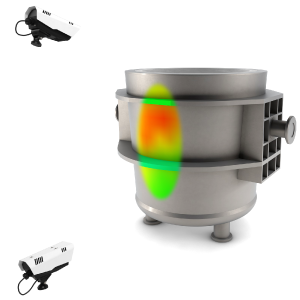

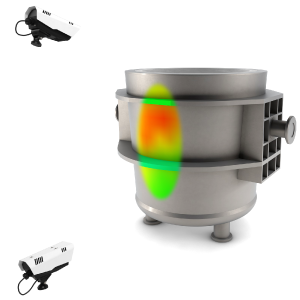

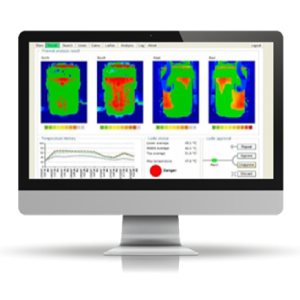

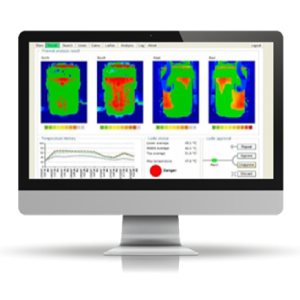

With VISIR – LadleSafe you can avoid unplanned production stops due to breakout related issues. Through infrared camera technology you can evaluate the steel structure thermal status of your ladles. Potential hot spots can be detected earlier than with the limited capabilities of the human eye.

The results are summarized in a recommendation which assists you in tracking down dangerous ladles. Based on the analysis results you decide if certain ladles are safe to continue using.

With VISIR – LadleSafe you can avoid unplanned production stops due to breakout related issues. Through infrared camera technology you can evaluate the steel structure thermal status of your ladles. Potential hot spots can be detected earlier than with the limited capabilities of the human eye.

The results are summarized in a recommendation which assists you in tracking down dangerous ladles. Based on the analysis results you decide if certain ladles are safe to continue using.

![]()

VISIR LadleSafe not only increases safety in the ladle handling areas but can also maximize the lifetime of your ladle refractory lifetime.

![]()

VISIR LadleSafe not only increases safety in the ladle handling areas but can also maximize the lifetime of your ladle refractory lifetime.

An expert dedicated to your area will get in touch with you.