Or even get rid of your old bricks? Give your bricks a second life and contact us for further information!

对不起,此内容只适用于美式英文。

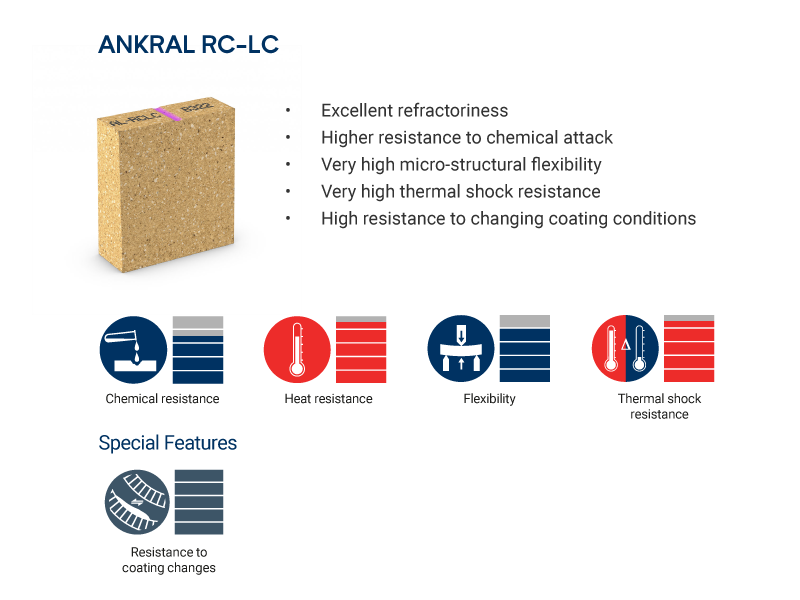

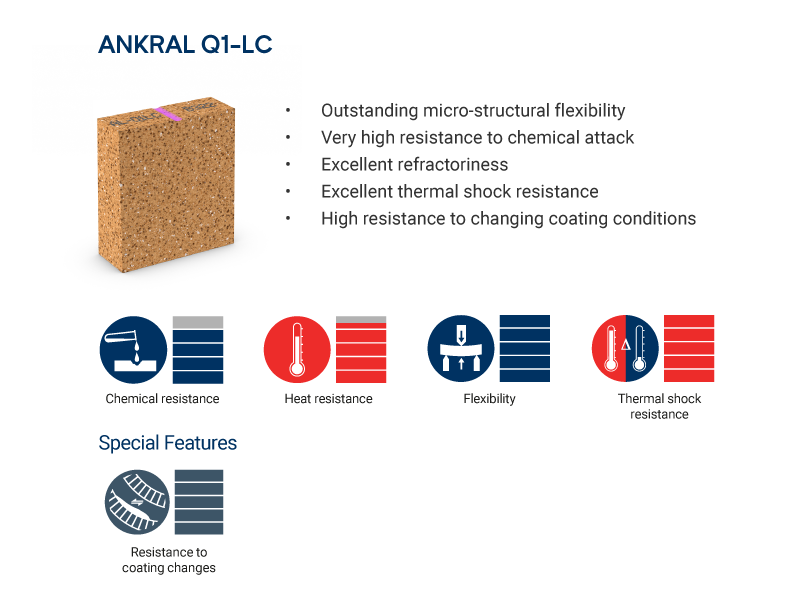

The ANKRAL LC Series is a high performance refractory product. It consists of a high amount of recycled raw material and as such, contributes to a reduced carbon footprint.

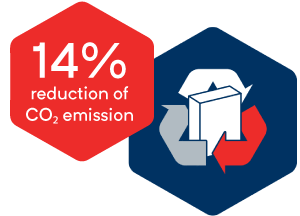

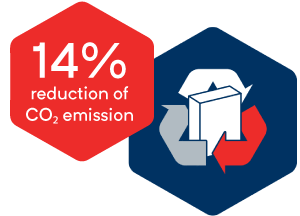

By using recycled material instead of primary Dead Burned Magnesia, the carbon footprint of the of the final product can be reduced by up to 14%.

By using recycled material instead of primary Dead Burned Magnesia, the carbon footprint of the of the final product can be reduced by up to 14%.

Dr. Christopher Ehrenberg

Plant manager of Lafarge Zementwerk Mannersdorf

Source: Pressrelease: Sustainability rocks

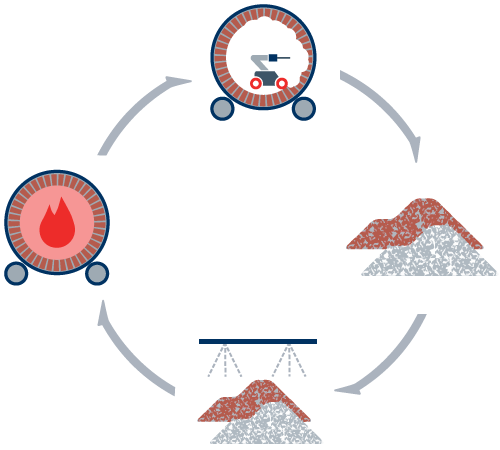

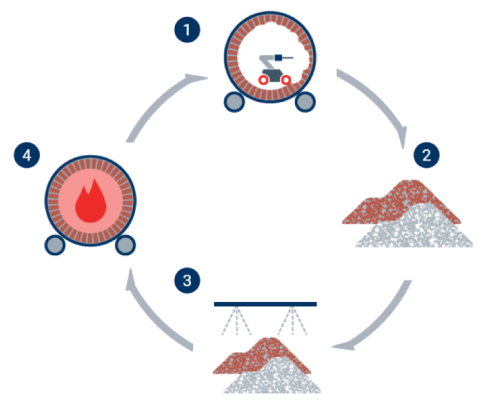

The circular economy approach is a process that starts and ends your kilns. It increases the lifecycle of our products by turning used refractory bricks at the end of their service life into a valuable raw material source.

We designed a process in order to increase the lifecycle of our products.

Discover in 4 easy steps how this practice increases the lifespan of the refractory lining:

1. De-bricking: After the stop of the kiln, it gets inspected and the material is dismantled.

2. Sorting & Declaration:

3. Reconditioning:

4. Start & End of Production

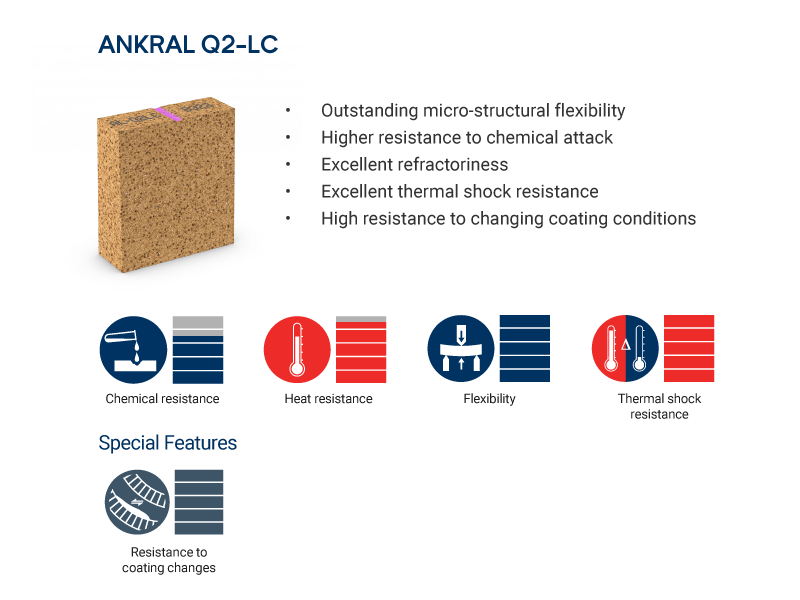

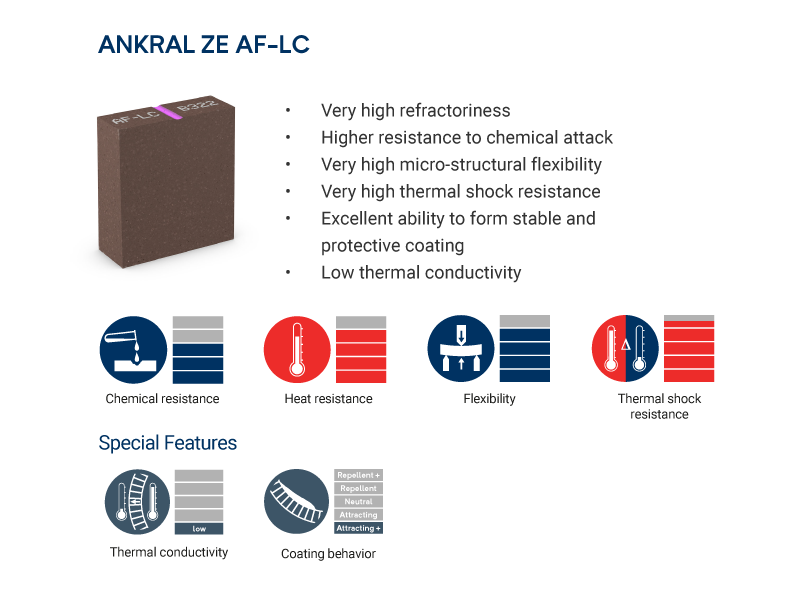

The LC-series product portfolio currently consists of four products for application under different operational conditions.

An expert dedicated to your area will get in touch with you.