We at RHI Magnesita have developed solutions customizable to consumers’ conditions and volumes, committed to a sustainable business model: The Circular Economy Model

Underpinned by applied R&D innovative technology, we act before used material perishes, from design to keep materials in use for as long as possible to design for recycling. Likewise, we transform waste into secondary raw materials for various applications, including other industries, helping you to have a positive impact on the environment while reducing your operative costs.

We designed a process in order to increase the lifecycle of our products.

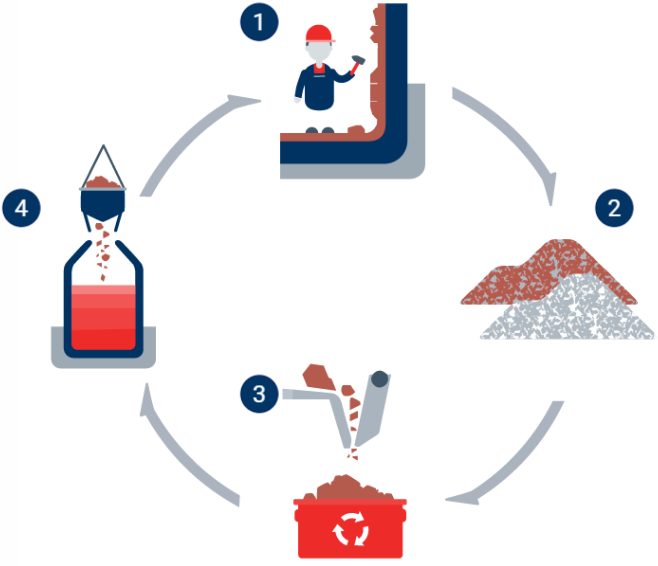

Discover in 4 easy steps how this practice increases the lifespan of the refractory lining:

We designed a process in order to increase the lifecycle of our products.

Discover in 4 easy steps how this practice increases the lifespan of the refractory lining:

1. The lining material gets torn-out by a skilled worker.

2. The material gets collected and separated.

3. The material gets grinded by crushing into a hopper/dump box.

4. Reuse material as crushed MgO flux addition.

Our customized solutions include:

By offering an onsite recycling facility, we enable the recycling of used refractory linings directly at your site by determining the optimal waste to value approach, such as: recovering waste material to produce secondary raw materials and/or returning the refined material to your steelmaking process as additional metallurgical additives instead of going directly to landfill.

We also offer the possibility of an offsite service. In this case we collect your spent material and recycle it in one of our facilities (Austria, Germany, Mexico, Brazil, Argentina, China and India).

An expert dedicated to your area will get in touch with you.