Reducing carbon emissions is a key priority for RHI Magnesita. In addition to charting its own transition, the Group want to be a trusted partner to its customers on their journey to a low carbon economy.

As an energy-intensive industrial producer, RHI Magnesita will focus on decarbonising the main steps of its production process but also on supporting customers on their journey towards a low carbon economy. The Group’s carbon footprint shows that 50% of its emissions are direct emissions (Scope 1). The short term target is a 15% reduction in CO2 emissions intensity for Scope 1, 2 (emissions caused indirectly by the company when the energy it uses is produced) and 3 (emissions caused by suppliers on the company’s value chain) (raw materials) by 2025, as compared to 2018 levels.

RHI Magnesita’s path towards a low carbon economy considers the implementation of breakthrough technologies and investment. Government support and a level playing field will be essential to ensure it can remain competitive. It also needs green energy in sufficient quantities and at competitive prices, more responsive “smart” electricity networks to help reduce emissions, and the necessary infrastructure for transportation and sequestration of CO2.

Climate change represents both strategic and operational risks to RHI Magnesita’s business. These are grouped as physical risks and transitional risks. Physical risks include greater severity of flooding, droughts or other extreme weather events which could disrupt operations or supply chain. Transitional risks range from new regulatory frameworks and market dynamics, technology and investor expectations related to climate change.

The Group updated climate-related risk analysis, highlighting increased financial risk from carbon pricing, notably due to CBAM (Carbon Border Adjustment Mechanism) implementation in the EU, which is an EU policy instrument designed to level the playing field for domestic producers subject to carbon pricing by implementing a carbon-based import tariff on goods from countries without equivalent carbon pricing. RHI Magnesita also refreshed its physical climate risk assessment, considering IPCC (Intergovernmental Panel on Climate Change) scenarios, assessing 29 categories of hazards. Find more details on climate governance, strategy, and risk management on the Group’s Task Force on Climate-Related Financial Disclosures (TCFD) reports.

Refractory production is a ‘hard to abate’ industry. Raw material processing typically relies on fossil fuels to ignite and burn carbonate rock, leading to CO2 emissions. Additionally, the manufacturing process demands significant amount of energy, which generates additional emissions. Finally, the transportation and delivery of refractory products to customers worldwide also contribute to emissions. These geogenic emissions are classified as Scope 1* when resulting from the Group’s own production or Scope 3 in the case of externally purchased raw materials. Significant energy is also required for firing of products in the refractory manufacturing stage. Further emissions are generated in the shipping and distribution of refractory products to customers worldwide.

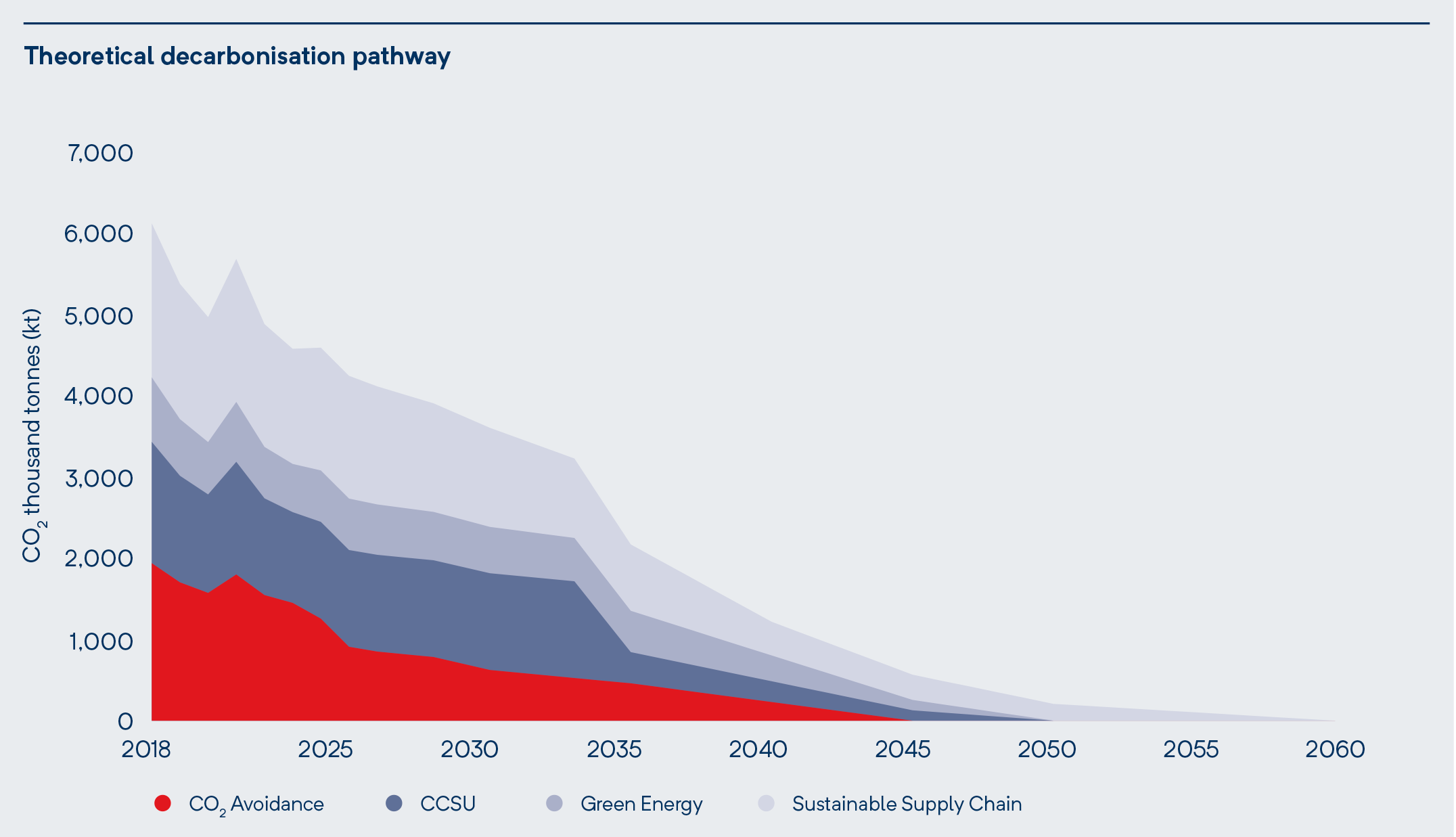

Through its investment in research and development of emissions avoidance or reduction technologies, the Group has developed a theoretical pathway to decrease its Scope 1, Scope 2 and Scope 3 (raw materials) carbon emissions from refractory production to close to zero.

* Scope 1 covers emissions from sources that an organisation owns or controls directly – for example from burning fuel in our fleet of vehicles (if they’re not electrically-powered)

* Scope 2 are emissions that a company causes indirectly when the energy it purchases and uses is produced. For example, for our electric fleet vehicles the emissions from the generation of the electricity they’re powered by would fall into this category.

* Scope 3 encompasses emissions that are not produced by the company itself, and not the result of activities from assets owned or controlled by them, but by those that it’s indirectly responsible for, up and down its value chain. An example of this is when we buy, use and dispose of products from suppliers. Scope 3 emissions include all sources not within the scope 1 and 2 boundaries.

The required measures have been prioritized in order of deliverability. The first stage of CO2 emissions reduction is to be delivered through measures which can be implemented by the Group without significant external support, including increased use of recycled raw materials, fuel switches and energy efficiency measures. It is estimated that these measures could deliver an absolute reduction of around 1 million tonnes of CO2 emissions, or 20% of the baseline total by 2035. Beyond this initial reduction, decarbonization measures become progressively harder to deliver. Recycling has a natural ceiling since refractories are consumed during use and only residual materials can be reclaimed, whilst fuel switches to natural gas only offer a partial reduction. The pathway for stages 2 to 4 is reliant on the provision of (i) new infrastructure or renewable energy sources such as hydrogen by outside parties; (ii) the use of technologies which do not yet exist or are not proven at pilot or production scale and (iii) significant capital expenditure, which may not be possible for the company to generate from its existing operations, obtain from its finance providers or receive via government funding.

Working within these limitations, RHI Magnesita is committed to:

1. Leading the refractory industry by decarbonizing its operations as fast as sustainably possible

2. Annually updating its decarbonization pathway based on the latest developments in technology, infrastructure and estimated capital expenditure

3. Continuing to invest in the development of new technologies to avoid CO2 emissions, proving technical readiness to use alternative low-carbon energy sources and to capture CO2 emissions for storage or utilisation

4. Offering customers enabling technologies for their own low-carbon production technologies together with low-carbon products and heat management solutions (with full transparency on carbon footprint) to enable them to reduce their Scope 3 (indirect) CO2 emissions from the purchase of refractories

5. Lobbying governments to invest in the necessary infrastructure to decarbonize the refractory, and other energy intensive, industries, including additional renewable energy generation, hydrogen supply networks, CO2 transportation and storage and carbon capture and utilization technologies

6. Collaborating with partners in the private sector to develop new renewable energy solutions, hydrogen energy networks and carbon capture and utilization technologies

The Group has significant CO2 emissions within its own value chain and there are large emissions savings that can be delivered for its customers through improved heat management or other solutions. The Board therefore considers that the priority should be to allocate capital and other resources to reducing the Group’s own CO2 footprint and the emissions of its customers rather than investing in carbon offset projects. The Board believes that taking this approach will deliver a faster, greater and more sustainable decrease in net CO2 emissions than could be delivered by allocating capital to offsets.

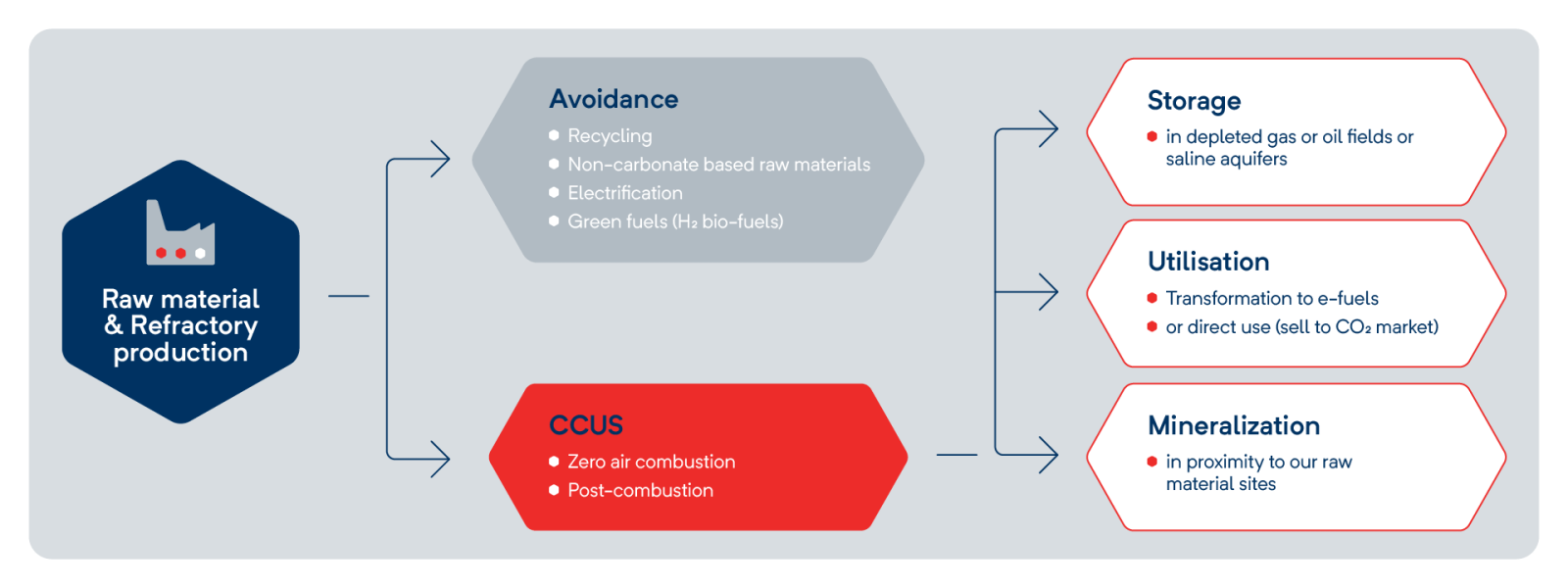

Refractory production is a hard to abate, energy intensive process with a high CO2 intensity. While switching to green fuels and recycling help reduce avoidable emissions, only Carbon Capture and Utilization (CCU) can address unavoidable process emissions. For instance, RHI Magnesita is collaborating with the Australian Green Tech Start-Up MCi Carbon to develop an innovative CCU mineralization technology that has the potential to eliminate process emissions.

In 2024, RHI Magnesita advanced its evaluation of CO₂ capture technologies, including cryogenic, chemical separation, and membrane-based methods. The company deepened its partnership with MCi Carbon to develop a process that mineralizes CO₂ from flue gases, converting emissions into solid minerals. This technology could also benefit industries like cement. Efforts in 2024 focused on building a pilot facility in Newcastle, Australia, with testing and development continuing until mid-2025.

More information about Carbon Capture and Utilization here.

RHI Magnesita has significant CO2 emissions within its own value chain and there are large emissions savings that can be delivered for its customers through improved heat management or other solutions. The Board of Directors therefore prioritizes the allocation of capital and other resources towards reducing the Group’s own CO2 footprint and the emissions of its customers rather than investing in carbon offset projects. Taking this approach will deliver a faster, greater and more sustainable decrease in net CO2 emissions than could be delivered by allocating capital to offsets.

RHI Magnesita leads the refractory industry in the use of circular raw materials. While recycled materials have historically been limited due to reduced performance, the Group has developed new technologies that enable higher recycled content without compromising quality.

In 2024, the recycling rate rose to 14.2%, up from 12.6% in 2023, moving closer to the Group’s target of 15% recycled material usage by 2025. This effort aligns with RHI Magnesita’s emissions reduction goal, as increasing the recycling rate is the single most important contributor to achieving the 2025 emissions intensity target.

Approximately half of the Group’s Scope 1 (direct) CO₂ emissions come from carbonate minerals during processing. By replacing virgin raw materials with recycled alternatives, around 1.5 tonnes of CO₂ emissions are avoided for every tonne of material reused—making recycling the most effective short-term solution to reduce emissions.

RHI Magnesita continues to expand its portfolio of low-carbon and circular products by integrating recycled raw materials across a range of solutions. These include refractory bricks with high recycled content, such as the ANKRAL LC series, low CO₂ refractory mixes for maintenance applications, circular metallurgical additives that support sustainable steelmaking. Together, these innovations aim to reduce the carbon footprint of industrial processes while maintaining high performance and supporting the transition to a circular economy.

To expand its recycling capabilities and accelerate the transition to a circular economy, RHI Magnesita has invested strategically in R&D, acquisitions, and infrastructure. Key initiatives include a joint venture with Horn & Co. in 2022, forming MIRECO and a dedicated recycling facility in Mitterdorf, Austria, which plays a central role in scaling circular raw material use and advancing sustainable production. During 2024 the acquisition of Refrattari Trezzi was completed, expanding the Group’s recycling activities in Europe.

In 2022, RHI Magnesita launched the ReSoURCE project, a 42-month initiative funded under the Horizon Europe framework. As the project coordinator, the company leads the technical direction and coordination, focusing on developing automated multisensor-based sorting solutions for spent refractories, ensuring high accuracy and reliability in material separation, and demonstrating clear sustainability benefits by enabling the recovery and reuse of materials in new applications. Learn more about ReSoURCE.

RHI Magnesita is committed to improving energy efficiency across its operations. In 2024, we achieved a 7% reduction in operational energy intensity—surpassing our 2025 target of 5%. Additionally, 9.3% of our total energy consumption now comes from renewable sources. In the same year, 78% of the electricity we purchased was from low-carbon or renewable energy, even though our Scope 2 emissions increased due to mergers and acquisitions. Notably, our sites in Austria, Germany, Scotland, Slovenia, Switzerland, Turkey, and Brazil now operate on 100% green electricity.

We are also actively exploring clean energy solutions to further reduce reliance on fossil fuels. RHI Magnesita is tackling the technical challenges of integrating green hydrogen into its production processes and is developing innovative concepts for future use. Beyond hydrogen, we are evaluating other non-fossil alternatives such as biomass. In 2023, our raw material plant in Breitenau, Austria, successfully trialed sunflower husks as a supplementary fuel source, highlighting our commitment to practical, low-carbon innovations.

As part of our ongoing sustainability efforts, we are targeting a 1% annual reduction in energy consumption (kWh) per site through 2030. This goal reflects our dedication to continuous improvement and responsible resource management.

To further strengthen our energy performance, RHIM is also committed to ensuring that 90% of the energy consumed at our plants in each business region is certified under the ISO 50001 energy management standard.

RHI Magnesita’s target is to reduce its nitrogen oxides (NOx) and sulphur oxides (SOx) emissions by 30% by 2025 as compared to 2018. This target was already achieved in China in 2021 and the current focus is now on North America. We significantly reduced NOx emissions in York, Pennsylvania, by implementing a two-stage combustion process in the rotary kilns. SOx reduction appliances have also been installed and are successfully reducing emissions.

Although the refractory industry is not typically water-intensive, responsible water stewardship remains a priority for RHI Magnesita. In 2024, the company withdrew approximately 10.1 million m³ of water from surface and groundwater sources. Notably, 23% of this volume was consumed in regions identified as being at risk of water scarcity—an increase from 16% the previous year. At Bhiwadi, India, a modification to the cooling system reduced water consumption by 17% and at Flaumont, France, a water underground storage system was implemented to protect nearby rivers from wastewater emissions. At present, ten sites operate in regions where water scarcity is or might soon become a risk, including Mexico, Brazil, India, China and France. RHI Magnesita is developing mitigation plans in these areas. In India, industrial rainwater harvesting pits at our Clasil site protected the plant from flooding during the monsoon while helping to recharge the aquifer with an estimated 30,000m3 of rainwater. With the prevention of flooding, it also helped in providing safe drinking water to local communities.

RHI Magnesita also works to drive down waste, using material previously discarded. The new rotary kiln in Brumado will use waste magnesite ore, almost halving the amount of magnesite ore we extract from the local mine, extending the mine’s life by over 70 years. The company also offers to collect waste at customer sites.

RHI Magnesita is committed to protecting biodiversity at its operational sites and is taking every possible step to minimise impacts on local plant and animal life. At the Brumado mine and raw material processing site in Brazil, the Group is required to restore land to its prior state after use, including planting native vegetation which matches that found in the local area. For this purpose and for wider community benefits, over 20,000 seedlings were grown yearly in the on-site tree nursery and planted inside and outside RHI Magnesita’s properties by employees and community members in 2024.

Over the past six years, we’ve planted more than 83,000 trees and expanded our forestation and reforestation efforts to 597 hectares annually since 2022. The Group has consistently managed over 17,000 hectares of forest, demonstrating its long-term commitment to protecting biodiversity and restoring ecosystems.