Leider ist der Eintrag nur auf English verfügbar. Der Inhalt wird unten in einer verfügbaren Sprache angezeigt. Klicken Sie auf den Link, um die aktuelle Sprache zu ändern.

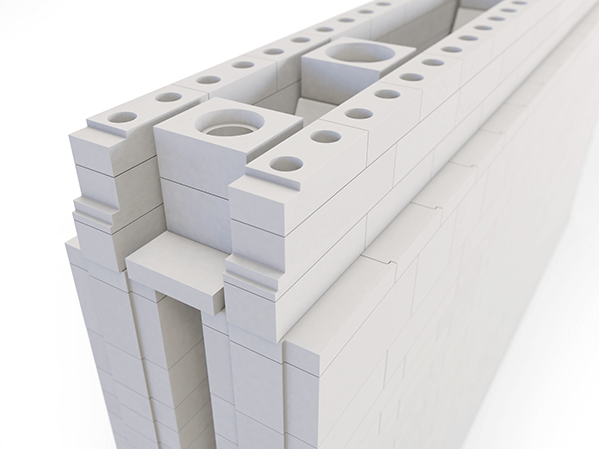

Coke oven batteries are one of the backbones in blast furnace steel production – but also very complex, cost intensive, and prone to gas leakages and damage. Wouldn’t you want to tackle all those challenges at once? Then discover our COMPAC COKE refractory block: Their high-quality, thermal shock resistant material and simple design ease your repairs, while significantly reducing your costs, energy consumption and emissions.

Make coke oven repairs a breeze

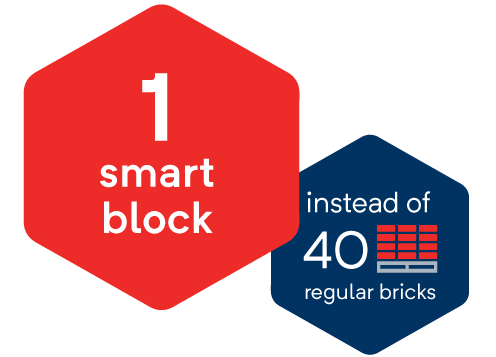

Conventional installations are often equipped with hundreds of different refractory shapes that are prone to cracking under heat. One of our cutting-edge, thermal shock resistant silica COMPAC COKE BLOCKs replaces up to 40 conventional bricks. The result: shorter installation time with less manhours. Their smart design makes your through-wall and end-flue repairs a breeze.

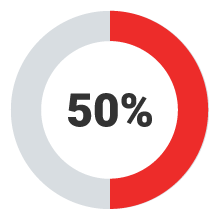

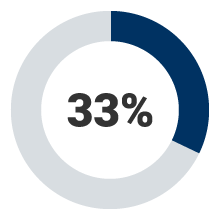

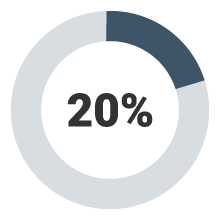

Reduce your efforts & resources in all areas

of regular

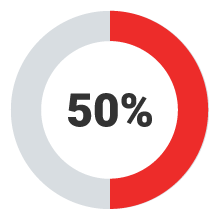

installation time

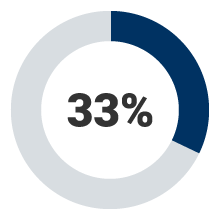

of regular manpower

for installation

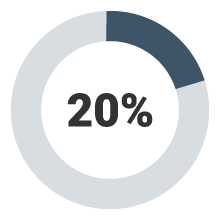

of regular

heat-up time

A new solution for an old technology

Conventional refractory design

- Very complex, labor intensive brick structure

- High costs for installation & maintenance

- Sensitive to damage through thermal and mechanical wear e.g. thermal shocks

- Thermal expansion over time

- Prone to gas leakages and pollution

COMPAC COKE BLOCK

- Fast heat-up due to low and predictable thermal expansion

- Lower costs through faster installation and coke output as well as significant gas savings

- Easy and fast handling, installation, and repairs through smart modular design

- Less emissions due to high gas tightness and efficiency

Key features

- High quality fused silica blocks with extraordinary creep strength

- High thermal shock resistance & dimensional stability with near zero expansion

- Smart, modular design with few joints – 1 block replaces up to 40 conventional bricks

- Highly efficient heat transfer through heating walls

- Fast lead-times

Get in touch

An expert dedicated to your area will get in touch with you.