Get insights about our digital services and solutions for the cement & lime industry and learn how to work smoothly, safe and cost-efficiently.

You want to improve your rotary kiln’s productivity and availability? You want to plan your stoppages based on facts and avoid safety incidents? With the Mechanical Kiln Audit, we can support you in evaluating the mechanical condition of your rotary kiln. Guided by our refractory and digital solutions experts, these regular audits will help you to optimize your production and prevent unplanned stoppages.

With the Mechanical Kiln Audit, we help you evaluate the mechanical condition of your rotary kiln.

Aim of the measurements is to raise the awareness and understanding of the mechanical condition of the kiln, and if required, to adapt the refractory lining and installation recommendation for the brickwork accordingly.

![]()

Regular Mechanical Kiln Audits will help you to optimize your production and prevent unplanned stoppages in the long run.

![]()

Regular Mechanical Kiln Audits will help you to optimize your production and prevent unplanned stoppages in the long run.

Optimize

We enable you to timely initiate maintenance measures and to optimize your refractory layout as well as installation procedures.

Save Costs

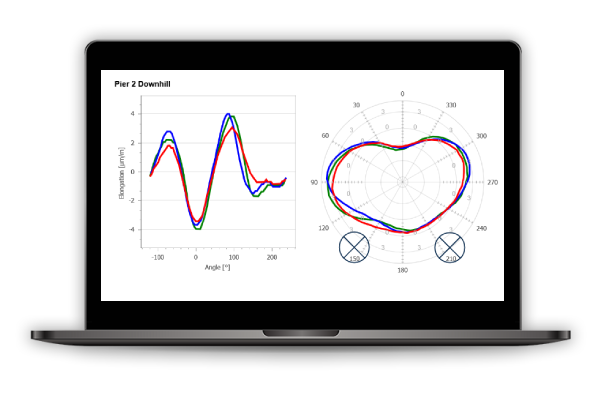

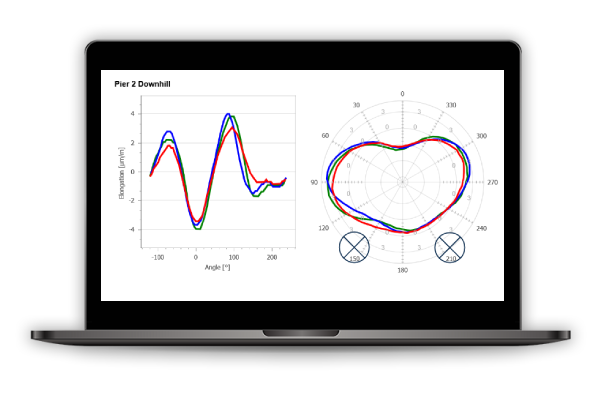

The evaluation of different parameters (tire migration, kiln axis eccentricity, ovality graphs and results, …) can support an early detection of upcoming issues and cost effective preventive maintenance can be carried out already at the next shutdown.

Tailored to your needs

Based on the findings you receive a detailed recommendation with proper selection of type / brand, shape combination, lining method (mortar or clench) and parking position of the kiln during installation can be given.

The assessment of the kiln condition is based on ovality tests carried out near the tire stations of the kiln, as well as the run-out tolerance of the shell over the complete length. Additionally, eccentricity, permanent deformations and roundness deviation can be displayed.

An expert dedicated to your area will get in touch with you.