- About

- Solutions

- Governance

- Investors

- Sustainability

- Sustainability

- Newsroom

- Jobs

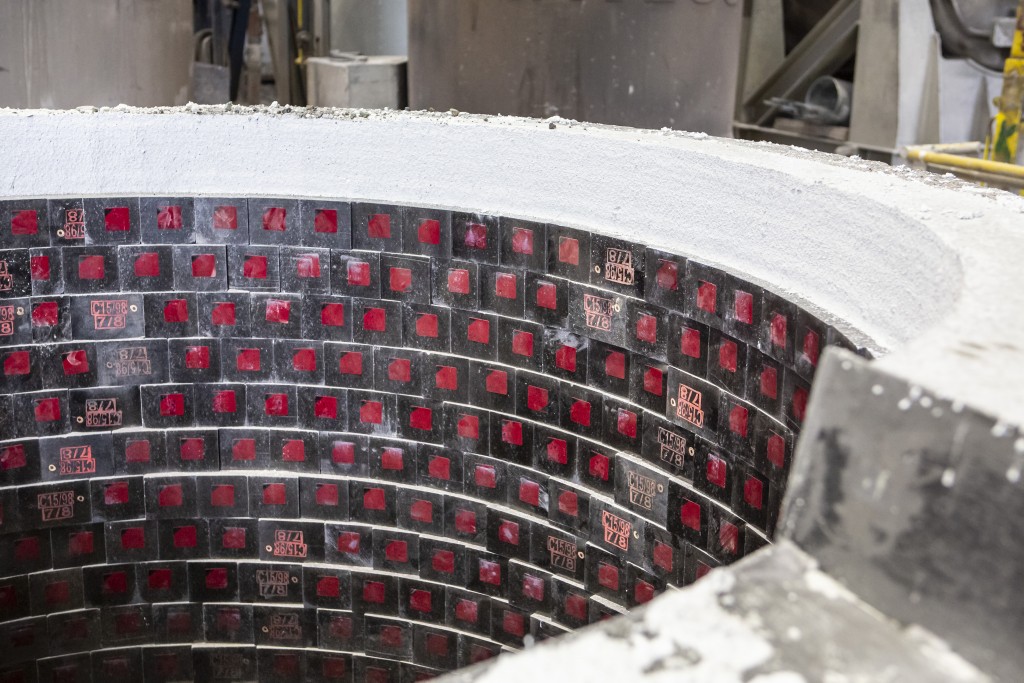

Our solutions are based on high alumina spinel-containing or spinel-forming castable materials.

Both types of castable have different final properties and their use is related to the application where mainly high mechanical strength or high elasticity is demanded.

Good flow and reliable workability with low content of mixing water are the controlling factors of an easy-to-use castable allowing a uniform distribution into the molds filling even smaller gaps. In addition, it is possible to pump/transport the material at relatively large distances.

A product of low viscosity and high content of solids is achievable by accurate particle distribution of all aggregates and the right selection of deflocculant dispersing agents.

The particular materials’ rheology determines the perfect adhesion to the remaining brick lining allowing the concept of “endless” lining which potentially reduces refractory consumption up to 30%.

Regular monitoring through accurate laser scanning enables effective control of the wear lining and a more efficient ladle management and safety. Besides that, it helps to manage the wear rate (0,8 to 1mm per heat in average) with a campaign performance up to 150 heats.