The blast furnace is the most used route for iron and steel production due to the numerous advantages it provides, such as low cost and high productivity. However, this process […]

Mehr lesen

In the sulphate process, Al2O3-SiO2 refractory bricks are used to line rotary kilns. During calcination of hydrated TiO2, these bricks are subjected to highly aggressive and corrosive SOx gas attack […]

Mehr lesen

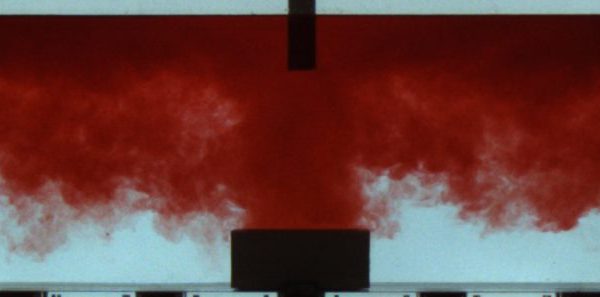

Off-centre and angled pouring of molten steel into the tundish by a misaligned ladle shroud can result in several problems caused by the asymmetric flow, such as short-circuiting flows, inhomogeneous […]

Mehr lesen

As modern steel plants and manufacturing processes evolve, additional demands are placed on refractory installation and performance. Many traditional tundish working lining materials require long drying and preheating curves, which […]

Mehr lesen

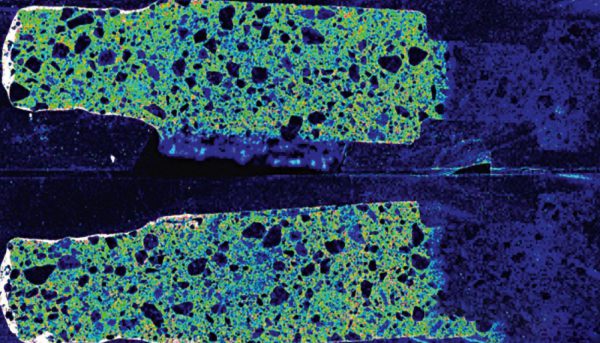

Determining the steel ladle refractory wear profile is a process used to ensure efficient and safe operation of the equipment throughout its campaign. Despite being an essential practice for steel […]

Mehr lesen

A major trend in continuous steel casting is the upgrade of flow control systems to meet new market demands. In addition to supporting clean steel production, ease of handling, and […]

Mehr lesen

As recycling has a significant impact on decarbonising the refractory industry, RHI Magnesita is pursuing various initiatives to increase reusing refractory products. This includes establishing MIRECO, the key partner for […]

Mehr lesen

The refractory industry is part of the most CO2-intensive value chains in the global economy and increasingly final customers are requesting the decarbonisation of these value chains (e.g., automobile production […]

Mehr lesen

RHI Magnesita is driving the refractory industry towards a carbon-neutral production footprint and in order to achieve this ultimate target, recycling is one of the most important strategic initiatives. Nevertheless, […]

Mehr lesen

Closing the loop of raw material flows through a circular economy and thereby finding sustainable refractory solutions is one fundamental strategic pillar of RHI Magnesita. In the last years, a […]

Mehr lesen

New electric arc furnaces (EAFs) with large melt volumes are expected to meet the required steel production capacity at minimum CO2 intensity during the green steel transformation period. As the […]

Mehr lesen

This article provides an overview of the roadmap, opportunities, and challenges of two promising process route alternatives for the green steel transformation of blast furnace–basic oxygen furnace (BF-BOF) plants. Since […]

Mehr lesen