Agellis®

Tellusgatan 15

22457 Lund

Sweden

Based on our two product platforms, EMLI (ElectroMagnetic Level Indication) and VISIR (Vision and Infrared), we supply an array of solutions to control the process and ensure operation safety.

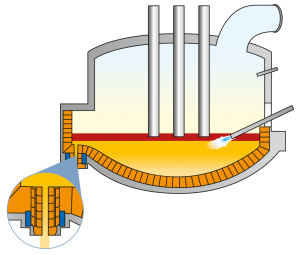

AGELLIS EMLI-FurnaceSlag constantly monitors the steel flow during tapping of the furnace and provides alarm outputs at the onset of slag in the stream. These outputs can be used to immediately end tapping by initiating gate/stopper closure or by changing furnace tilt angle, while at the same time giving visual and audible alarms.

Sensors/cabling are customized to fit any furnace. Tap-hole sensor arrangement requires only minimal modification to existing equipment. The Management Unit is capable of running multiple Control Units of the same or different EMLI system types. This enables the user to expand the system to run extra slag detection systems and/or other EMLI measurement devices. Steel plant tested components make the EMLI System extremely durable with low maintenance costs. Sensors require no special handling or cooling.

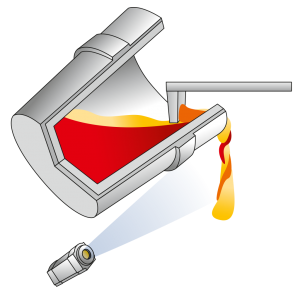

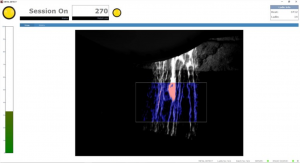

Agellis VISIR-MetalDetect improves your metal yield through detection and control of metal losses in the deslagging process.

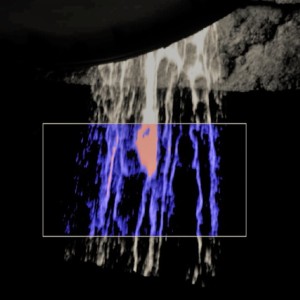

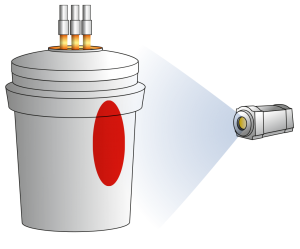

The VISIR-MetalDetect system is designed to monitor the ladle or furnace deslagging operations in order to detect when metal is being poured. Thus a minimal amount of metal is lost and yield improved.

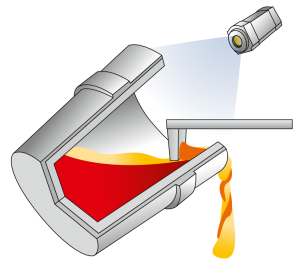

MetalDetect uses a thermal camera and vision technology in order to monitor the deslagging operations in real time.

By using the VISIR-MetalDetect system you will be able to assist operators to control their deslagging metal losses in a safe and secure manner. The thermal camera mounted behind the deslagging stream will monitor the process automatically and inform the operator when metal is detected so that they can modify the process quickly and safely.

By better control of the deslagging process variations and ensuring that the metal losses are significantly reduced, yield improvements and consistency can be achieved.

The VISIR-MetalDetect system will automatically track and store vital information for each heat and make sure your yield and quality assurance program is met every time.

The VISIR-LadleDeslag system monitors ladle skimming operations to help achieve clean ladle steel for further process operations, while at the same time ensuring that excessive metal loss is avoided. VISIR-LadleDeslag cameras and software evaluate the ladle surface slag content and feeds information to the operator when a sufficient skimming has been achieved.

Are you experiencing uncontrolled sulphur increases in the BOF? Are you experiencing uncontrolled reoxidation during ladle treatment? Do you feel a need to narrow down process variations in the final steps of processing? Do you see that the deslagging performance varies considerably from ladle to ladle and is operator dependent?

If you associate with any of the above, VISIR-LadleDeslag will assist you in solving your problem.

Carryover slag variations in ladles are often the cause of a number of problems detrimental to processing and product quality. Unforeseen reoxidation reduces alloying yields and refining efficiency forcing the operator to deviate from the standard processing and take additional processing steps. The added oxygen also contributes to the formation of non-metallic inclusions that lowers product quality.

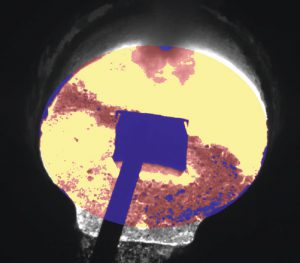

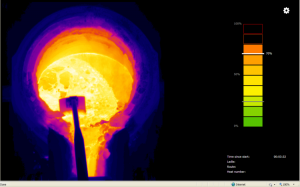

VISIR-FurnaceSafe infrared monitoring of your furnace shell minimises the risk of liquid steel breakout and maximises your operational furnace availability while at the same time increasing safety.

The risk of a breakouts will always be present in steel making with equipment damage, personnel injuries and loss of production as the consequence.

VISIR-FurnaceSafe continuously monitors the furnace shell thermal status and trends temperatures covering over 100 000 measuring points.

The monitoring system automatically alerts you when detecting early signs of dangerous hot spots, helping you to handle the situation before it becomes a hazard.

VISIR-FurnaceSafe stores data in a measurement database, letting you create weekly reports and evaluate refractory performance.