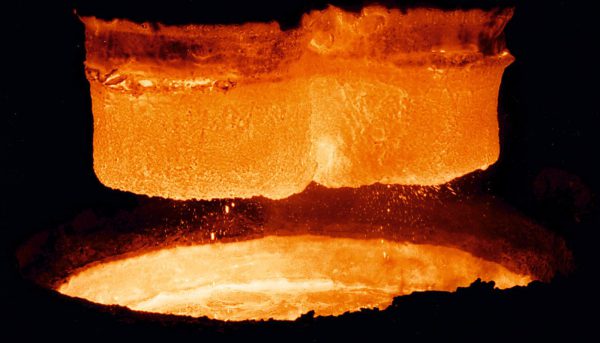

Freeze lining (FL), a protective layer of solidified slag, holds significant economic value in industrial processes. It protects furnaces and refractory linings from corrosive molten slag and acts as a […]

Read More

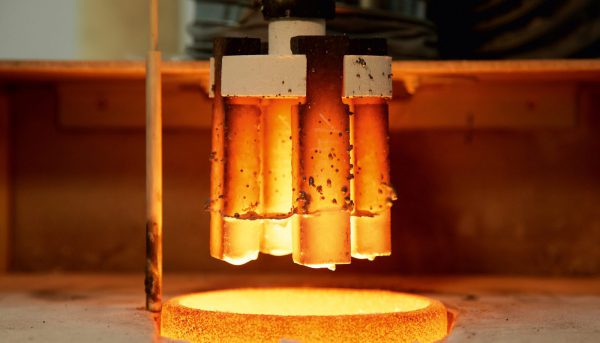

As the most relined vessel in a steel plant, the tundish can be very time-consuming and work-intensive regarding lining frequence, drying, and preheating. Therefore, when it comes to the modern […]

Read More

Refractories and flow control systems for clean steel casting are technology drivers because the demands on steel cleanliness are permanently increasing. Clogging and nonmetallic inclusions in steel not only contribute […]

Read More

The refractory industry plays a pivotal role in various high-temperature industrial processes, such as cement and nonferrous metal production, steelmaking, and glass manufacturing. As environmental concerns intensify, there is a […]

Read More

Flexospheres are a recent product development successfully implemented in fired magnesia-chromite bricks at RHI Magnesita. This technology focuses on inhibiting the corrosion mechanism and increasing flexibility of the refractory product. […]

Read More

Desulphurisation in the steel ladle requires a reactive slag with high CaO dissolution. Conventional slag fluxing agents applied during this secondary metallurgical refining step include calcium aluminate additives and fluorspar […]

Read More

Optimum management of steel ladles plays a crucial role for efficient and sustainable steel production. Regarding ladle wear linings, steelmakers typically have two main approaches. The most common is a […]

Read More

Global efforts towards decarbonisation have recently gained support from various industries. One of the most feasible paths to reduce carbon emissions is by implementing hydrogen as a fuel and/or a […]

Read More