- About

- Solutions

- Governance

- Investors

- Sustainability

- Sustainability

- Newsroom

- Jobs

The ironmaking industry increasingly seeks accurate modelling of operational variables to predict refractory wear in blast furnace main runners. Understanding the factors influencing refractory wear enables safer, more cost-effective, more sustainable, and high-performance hot metal production. However, this task remains challenging due to the complex and often nonlinear interactions between process variables, which are not yet fully understood. Traditionally, industry decisions rely on experience or indirect methods. This study presents a robust predictive model to support process engineers in forecasting refractory wear in blast furnace main runners. By integrating unsupervised clustering techniques with a meta-regressor, a high-precision model for predicting refractory wear was developed. The results provide valuable insights for optimising operational strategies, extending refractory lifespan, and enhancing decision-making in blast furnace operations.

The blast furnace route remains the dominant steelmaking process due to its high productivity, continuous operation, and cost efficiency. Recent advancements in process control focus on improving energy efficiency and reducing emissions in hot metal production.

One of the main challenges in blast furnace operations is optimising tapping practices and runner designs in the casthouse area. The performance of refractory linings in main runners is critical for operational stability. Well-designed systems reduce worker exposure in the casting area and improve safety. Enhancing refractory performance through advanced technologies, from installation to predictive monitoring, increase productivity and efficiency.

In an era where Industry 4.0 and digitalisation are reshaping industrial processes, leveraging big data, artificial intelligence, and predictive modelling has become a key differentiator for competitive advantage. RHI Magnesita stands at the forefront of this transformation by integrating sophisticated analytics into refractory wear prediction for blast furnace runners, moving beyond traditional monitoring methods towards proactive decision-making tools. By combining scanner measurements with production data, an algorithm identifies critical wear patterns, such as higher corrosion rates during process initiation or throughout blast furnace runners’ operation. This analytical approach aligns with a published framework [1], which highlights the strategic importance of data-driven decision-making in outperforming industry peers. By investing in advanced predictive models, RHI Magnesita strengthens operational reliability, reduces unplanned downtime, and enhances process efficiency, ensuring its leadership in refractory solutions for the iron and steel industry.

During operation of the main runner in the blast furnace casthouse, various complex chemical and physical wear mechanisms act simultaneously, promoting degradation of the refractory working lining through contact with molten hot metal and slag at high temperatures [2,3]. Certain operational practices in the casthouse, as well as intermittent furnace operation—requiring successive drainages of the main runner throughout its campaign—further accelerate refractory wear due to increased thermal cycling and the resulting thermomechanical stress on the runner’s castable material.

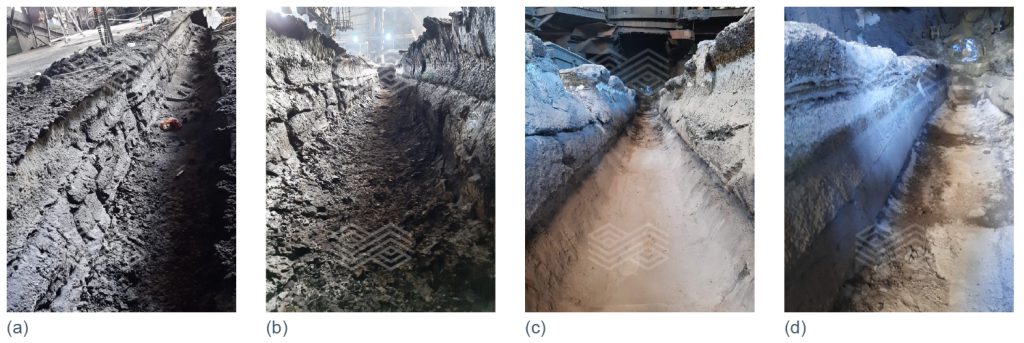

In many cases, draining the main runner is necessary to directly assess the remaining thickness of the refractory castable wall. Through inspection, in which the remaining thickness is measured, it is possible to safely estimate a maximum campaign limit for the runner. Practical examples illustrating the influence of the number of main runner drainages on cracking and the remaining refractory thickness are shown in Figure 1.

Figure 1. Influence of main runner drainages on the working refractory lining. Inspection results at the end of the campaign for a runner with (a, b) 6 drainages during operation and hot metal production of 106912 tonnes, and (c, d) 2 drainages during operation and hot metal production of 111415 tonnes.

It was observed that in the same main runner of a blast furnace, with an average production of 10000 tonnes/day, operated under the same campaign conditions in terms of hot metal production, the formation of surface cracks on the working lining was directly influenced by the number of drainages. This example highlights that the operational intermittency of the runner induces complex thermomechanical mechanisms in the lining castable, intensifying its expansion and contraction, which consequently leads to crack formation. These cracks in the refractory lining significantly increase the operational risk of the main runner, making it more susceptible to hot metal infiltration when returned to operation.

In addition to the operational risks that the main runner is exposed to from successive drainage cycles, the metallic losses resulting from this process must also be considered. The hot metal removed during runner drainage cannot be reused in the subsequent steelmaking route and is instead discarded and processed as scrap. This hot metal scrapping increases production costs and negatively impacts CO2 emissions, as for every 1 tonne of hot metal produced, approximately 2 tonnes of CO2 gas are emitted [4].

For the runner wear inspection, laser scanning is used as a benchmarking methodology, enabling a comprehensive assessment of wear across the entire runner lining with high precision, regardless of the temperature of the remaining material. Additionally, the laser scanning technique allows for highly accurate monitoring of wear in the entire slag line region of the runner, particularly in designs where this region remains exposed between tapping cycles. All wear data generated through laser scanning is digitised using automation software, which almost instantly overlays the point cloud of the new (reference) runner with that obtained after the start of operations [4,5]. The laser scanning method for the runner was employed in the development of this model.

For construction of the predictive algorithm to assess wear of the blast furnace main runner, unsupervised machine learning techniques were applied. This method identifies complex patterns in existing data and uses them to make predictions on previously unknown data [6]. In the process under discussion, clustering was performed based on the cumulative tapped hot metal. Subsequently, four regression models were individually trained. These models generate their respective predictions, and the final forecast is obtained by averaging their outputs. A flow chart of the developed machine learning system is shown in Figure 2.

The technique used is known as ensemble learning, employing the Voting Regressor method to generate the final prediction [7,8]. The principle behind this approach is that combining predictions from different models can reduce both bias and variance, resulting in a more accurate forecast.

The data acquisition frequency used for constructing the models during a runner campaign was as follows:

Using historical data from two years of main runner campaigns—combined with information on the refractory lining quality, installation parameters, and process variables from two different blast furnaces—a predictive model was implemented to estimate the wear of the main runner’s working lining for each blast furnace. The model’s predictions were then compared to actual measured wear to evaluate accuracy. The results showed a maximum relative error of less than 20% in predicting the remaining wall thickness of the runner lining. Given that at the end of a runner’s campaign the minimum allowable remaining wall thickness is approximately 200 mm, this corresponds to a maximum absolute error on the order of 40 mm. Figure 3 presents the predicted remaining refractory thickness for a specific tapping cycle of a blast furnace runner, along with the corresponding safety margin for that prediction. Notably, the model’s accuracy in estimating the remaining slag line thickness at the end of the runner’s campaign was approximately 90%, which is considered very high for this application.

One challenge in wear measurement is that the remaining lining thickness at the hot metal line of the main runner can only be obtained after draining the runner. During normal operation, this region is submerged under the metal bath, which prevents the laser scanner from capturing the lining profile in that zone. Being able to accurately predict the wear at the hot metal line through mathematical and statistical correlations with the slag line wear and operational data becomes a highly valuable tool for the customer, as it enables more informed and safer decision-making. This approach provides operators with important information that would otherwise only be available via a risky and time-consuming drainage procedure.

Figure 4 shows the model-predicted and actual measured values for the hot metal and slag lines, considering the minimum remaining refractory thickness during runner campaigns of CSN’s Blast Furnace 3 (4 tapholes and an internal volume of 4250 m3). Across all analysed cases, the model predictions closely followed the trend of the measured data, with relatively low deviations. Notably, for the 1st campaign in 2025 (main runner #1 and #2), the model showed high accuracy for both the hot metal and slag lines, with discrepancies of less than 10 mm—corresponding to deviations under 2.5% of the total remaining refractory thickness. For the 4th and 5th campaigns in 2024 (main runner #1, #2, and #4), deviations also remained within moderate ranges, albeit with slightly higher local variations, yet still falling within acceptable limits for industrial refractory wear prediction applications.

Such performance indicates that the model possesses robust generalisation capacity, effectively capturing the dominant mechanisms driving refractory wear in the hot metal and slag line regions. The observed level of accuracy substantiates the model’s applicability in operational environments, both as a decision-support tool for maintenance planning and as a reliable framework for validating operational strategies aimed at extending the campaign life of the main runner lining.

One of the most significant practical benefits of the predictive model is its ability to extend the main runner campaign without requiring drainage for inspection (i.e., enabling “hot” condition monitoring of wear). Whether this extension is feasible depends on the confidence in the model’s accuracy, which in turn is built upon the laser scan measurements of slag line wear taken during operation, as well as the blast furnace’s operational parameters and the specific characteristics of the castable lining considered in the model.

Figure 5 illustrates substantial campaign extensions achieved for a main runner at Ternium Brazil’s Blast Furnace 2 (which has two tapholes) using the model’s predictions. In this case, the end-of-campaign criterion for the runner was the remaining thickness at the hot metal line. The model was used to predict the hot metal line wear based on the observed slag line wear, eliminating the need for runner drainage. By relying on the model’s accurate predictions, the operators were able to safely extend the runner’s campaign beyond the point where, traditionally, a drainage would have been performed, thus optimising the runner’s service life using technical and reliable information.

In addition to accurately predicting the remaining campaign of the main runner’s refractory lining, the insights generated by the applied machine learning techniques are enabling a deeper understanding of the wear mechanisms affecting the runner. For example, data analysis has revealed a clear correlation between continuous runner operation (with minimal drainages) and reduced wear rates, in contrast to the accelerated damage seen with frequent cooling cycles (as in the case of multiple drainages). These findings corroborate operational observations and provide a quantitative basis to evaluate different practices.

The use of this predictive model to assess the remaining refractory lining thickness of the blast furnace main runner—by intelligently combining blast furnace process data, laser scan measurements of the remaining lining, and information on the refractory material and its installation—provides substantial value to casthouse operations. This digital monitoring tool significantly enhances operational safety and reduces worker exposure by minimising the need for manual inspections in the casthouse. It can eliminate the need for premature runner drainage, thereby avoiding the associated hot metal production losses and preventing unnecessary CO2 emissions from reprocessing the lost metal. Moreover, it increases equipment availability by allowing the runner to remain in service for its optimal campaign length. In summary, this predictive wear monitoring solution, developed by RHI Magnesita, empowers our customers to achieve safer, more efficient, and more sustainable blast furnace operations.

As a next step, the model is expected to be adopted by a broader range of customers. This expansion will not only support scalability and generalisation, but will also enrich the data set, enabling further model improvements and a deeper understanding of the underlying processes.

[1] Davenport, T.H. and Harris, J.G. Competing on Analytics: The New Science of Winning; Harvard Business Review Press: Boston, 2007.

[2] Domiciano V., Ribeiro, A., Araujo R., Ollmann, A., Bassalo, H. and Brito, M. Concreto Refratário para Condições Operacionais Críticas de Canais de Corrida de Altos-Fornos. Presented at 45º Seminário de Redução de Minério de Ferro e Matérias-primas, 16º Simpósio Brasileiro de Minério de Ferro e 3º Simpósio Brasileiro de Aglomeração de Minério de Ferro. Rio de Janeiro, Brazil, August 17– 21, 2015, 690–696.

[3] Duarte, A., Ollmann, A., Reis, G., Bassalo, H., Brito, M. and Domiciano, V. Influência dos Teores de FeO e MnO da Escória no Desgaste de Refratários de Canais de Corrida de Altos-Fornos. Presented at Redução de Minério de Ferro and Tecnologia Mineral. Belo Horizonte, Brazil, September 19–22, 2010, 603–613.

[4] Macedo, J.F., Ribeiro, A.S., Nonaka, F., Guimarães, B.F., Morais, V.L. and de Ávila, H.C. How 3D Laser Scan is Adding Value and Performance to Refractory Lining Inside Steel Industry. Presented at AISTech Technology Conference, Pittsburgh, USA, May 16–18, 2022, 1508–1520.

[5] Kollmann, T., Spiess, B., Fonseca, D., Christmann, K., Conceição, P., Kek, F., Freiler, M., Kirschen, M., Ribeiro, A. and Kirowitz, J. Refractory Solutions in Integrated Steelmaking to Decrease CO2 Footprint and TCO Level. Presented at the 9th European Oxygen Steelmaking Conference (EOSC), Aachen, Germany, October 17–22, 2022.

[6] Zhou, Z.H. Ensemble Methods – Foundations and Algorithms; CRC Press: Boca Raton, 2012.

[7] Bishop, C.M. Pattern Recognition and Machine Learning; Springer: New York, 2006.

[8] Huyen, C. Projetando Sistemas de Machine Learning: Processo Interativo Para Aplicações Prontas Para Produção; Alta Books: Rio de Janeiro, 2024.